Designing a 3d model using Shapr3d to export as a .stl or .3mf file:

Slicing the finished .stl or .3mf 3d model using Anycubic Slicer Next and preparing supports for overhanging sections that will not be able to print in thin air:

The Anycubic Kobra 3 Combo gets to work printing the sliced model. God it’s good!

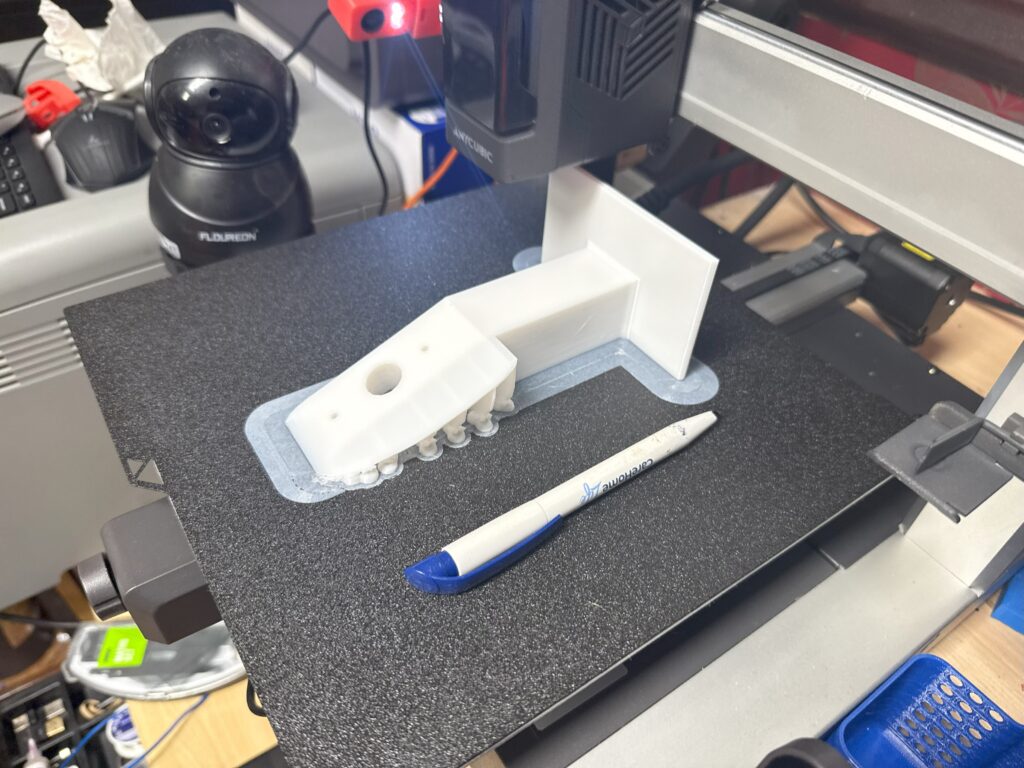

Nearly done. Just sent the customer a picture of the model with a pen next to it so he can get an idea of the relative size of it:

The model has finished printing! The supports will need to be peeled off.

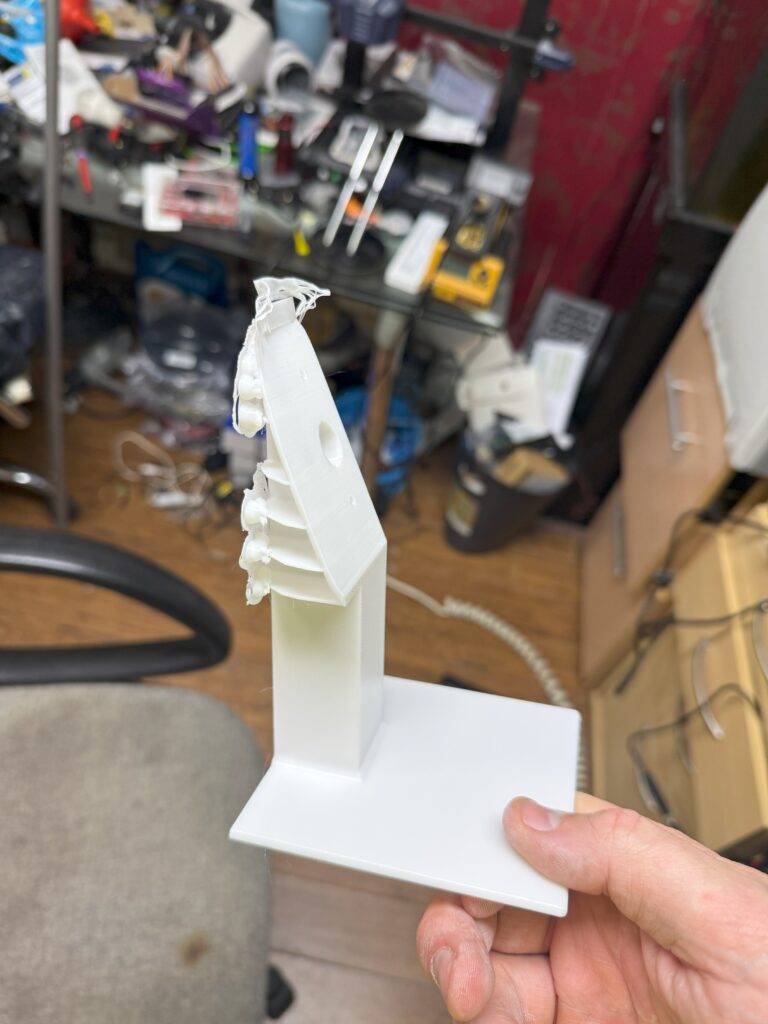

Another angle:

And another angle! That’s all the ‘brim’ hanging off which helps it stick to the build plate. There’s nothing worse than after printing for hours; the model falls off the build plate and the printer releases spaghetti for hours until it’s stopped because it’s trying to print in thin air! I will have to capture my next failed print to share the photos of this happening. It looks quite funny to someone who is not desperately trying to get a model finished!!!

Here is the finished print… there’s two of them and the other one is a mirror image of the first one because they are going to be camera mounts to go onto the side of a training bus as the examiner needs to have a display screen where they can see down both sides of the bus to check if the person doing their bus driving test hits the kerb or any stray pedestrians or the like!